6 basic tips for the correct maintenance of your equipment

Keeping detailed service record helps maximize heavy equipment machine life.

In the construction, earthmoving and mining sectors, heavy equipment is the largest investment, and the most expensive to replace. Proper Maintenance is a vital factor in the return of your machinery investment.

In Blumaq, we are aware of the importance of keeping your machine service or maintenance downtime as short as possible, so we offer you 6 basic tips to avoid premature failure and maximize continuous periods of work.

1) Get to know your machines inside and out

Service manual and owner’s manual contain useful information for troubleshooting. Experienced operators are also an excellent source of information about the equipment they operate in a daily basis.

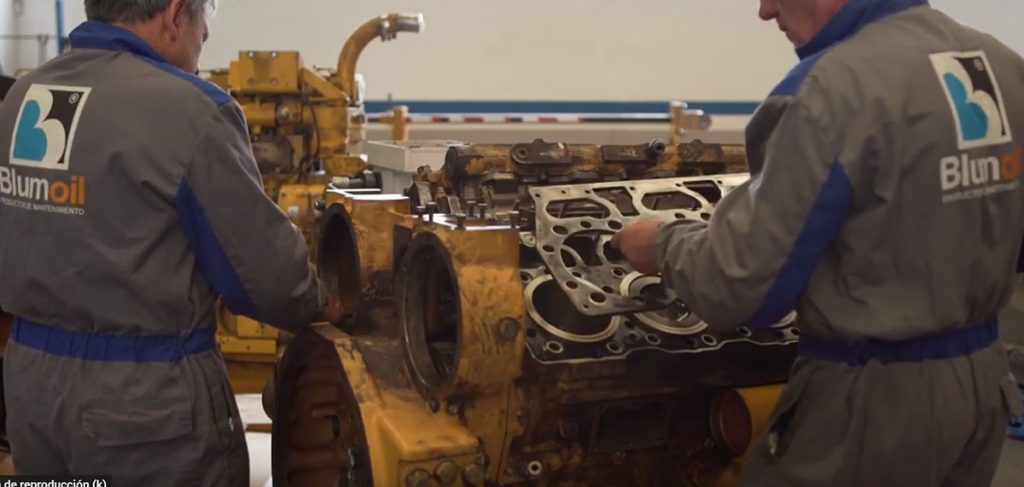

2) Choose trained and experienced personnel to service your machine.

The training and experience of the staff is essential, not only in the case of repairs, but also in regular maintenance. An experienced mechanic will be able to see the situations of possible risk during routine maintenance, and will provide you with solutions, thus avoiding future and more expensive repairs.

3) Lubrication is essential. Vibrations in the chassis, friction and age of the machine are factors to be taken into account.

Vibrations may be the result of badly conditioned or incorrectly aligned bushings, silent-blocks or friction plates. High temperatures due to prolonged use of the machine, low lubrication of the parts or the age of the machine itself may increase the need for revisions of the articulation system or chassis.

Good lubrication reduces friction between materials, which is the most important part of maintenance. Control of the fluid levels provides us with information about the correct functioning of our equipment, it should be done frequently.

Always use lubricants and additives of proven reliability.

4) Keep your equipment clean.

It seems difficult, but it is possible, despite the place where you work, you should try to keep your machine always clean. The filters have to be checked and changed regularly. Cabin filters should be kept clean to facilitate air renewal. The installation of a pre-filter will protect your engine from external bodies that could be absorbed by the air intake and cause a breakdown in your turbo or engine.

5) Updated service history record

Know your equipment needs and record maintenance and repair services. It is impossible to remember in detail the repair and maintenance history of a certain machine. Keeping a log book will help you schedule future maintenance and anticipate routine services. Repair will be easier and, more important, faster if you can prepare the parts and notify the technicians in advance. This is the reason for keeping a detailed record.

6) Establish routine pre-checks.

If the operator performs a pre-check before turning on the machine, he will be able to notice possible problems that will be future repairs. It may be useful to prepare a list of points to check such as the operation of lights, windshield wipers and other electrical systems, tire or undercarriage visual check, engine, transmission and hydraulic oil levels, hose leaks and others that you consider important depending on your equipment working environment.

In Blumaq we want to help you, with our spare parts, with technicians and service, and also with these tips to keep your machine always in perfect condition, so you get the best return on your investment.

Blumaq is a guarantee of quality, committed to you.